Description

Colors and sizes can be customized:

| Specification | |

| Name | 4 Bedroom Modular Home (135sqm) |

| Size | 10000mm*14000mm*3200mm(H) |

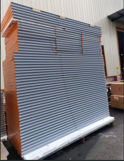

| Shipment | 1 Set/40GP |

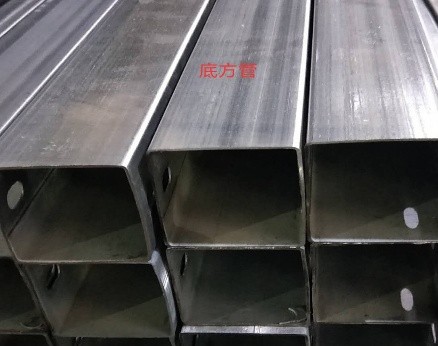

| Structure | Electro Galvanized Steel Structure with Anti- rust Painting |

| Wall | EPS/Rockwool/Fiberglass wool/ Phenolic/PU Sandwich Panel |

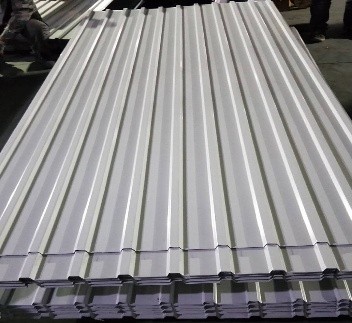

| Roof | Corrugated Roof Sheet with Fiberglass wool/ Steel Gable Roof |

| Ceiling | Corrugated Metal Sheet/PVC/Gypsum Board |

| Floor | MGO Board/Fiber Cement Board/PVC/ Composite Wood/Tile Floor |

| Window | PVC/Aluminum Sliding Window |

| Door | Single Steel/Roll-up/Double Sliding/Folding Glass Door |

| Electric | LED Lights , Switches & Sockets , 2P 63A Distribution Box |

| Plumbing | UPVC/PPR/PB/PERT |

| Color | Light Grey, White |

| Technical Data Sheet | |

| Wind Load | Grade 12 , 125kph |

| Seismic Load | Grade 10 |

| Snow Load | 0.6KN/㎡ |

| Live Load | 0.6KN/㎡ |

| Floor Load | 140KG/㎡ |

| Wall Impact Load | 0.6KN/㎡ |

| Wall Heat Transfer Coefficient | 0.35KCAL/㎡ |

Common materials for the prefab building:

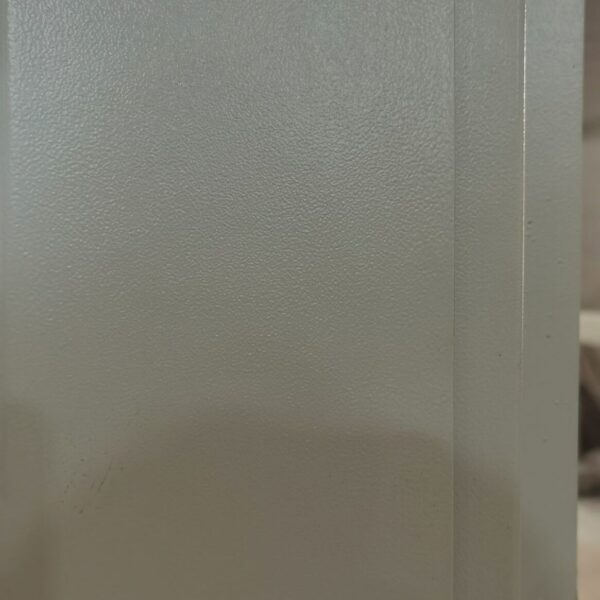

Anti-rust: Peel Baked Coating

#Orange Peel Baked Coating VS #Smooth-Finish Baked Coating

Our Prefab Container Homes with Durable Orange Peel Texture Paint.

Built to withstand the toughest environments, our modular container homes feature orange peel Baked Coating – a robust finish that’s both abrasion-resistant and scratch-proof.

Installation:

1. No need crane.

2. 2 workers 3 hours can finish 1unit.

Our Packaging:

1. All components will be wrapped with film to prevent scratches during transportation.

Loading Service:

1. If there are other goods, we can help to load.

2. If customers have purchased products from other placesand need to be loaded together, we can provide containerloading services for free.

Reviews

There are no reviews yet.